Sensors.co.uk

Sensors.co.uk

Energy heat meters

Sensors.co.uk

Sensors.co.uk

Coltraco Ultrasonics

Energy heat meters

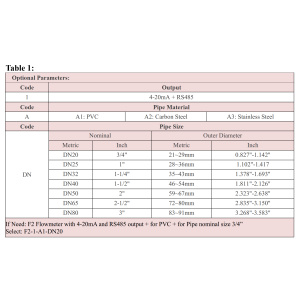

Ultrasonic clamp-on heat flow meter Type: BFU-100-M-M (50-700 mm)

Energy heat meters

Ultrasonic clamp-on heat flow meter Type: BFU-100-M-S-C (40-100 mm)

Ultrsone Flowmeters

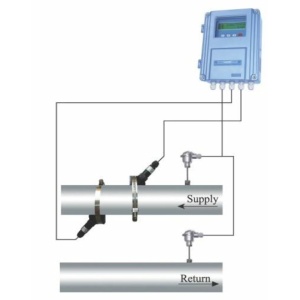

Ultrasonic flow meters use ultrasonic sound waves to measure the flow rate of a fluid. They typically consist of a pair of ultrasonic transmitters and receivers placed on either side of a tube through which the fluid flows.Transit-Time Method:

This is the most commonly used technique in ultrasonic flowmeters. In this method, ultrasonic pulses are sent with the direction of flow and sent against the direction of flow. The time difference between these pulses is measured. With flow in the direction of the sound waves, the travel time decreases, while with counterflow, the travel time increases. Thus, the difference in transit time indicates the flow velocity.

Doppler Method:

This method uses the frequency change of ultrasonic waves as they reflect off moving particles in the fluid. The Doppler effect is used to measure the velocity of particles in the liquid. Although this method is effective in measuring the velocity of particles, it is usually used in applications with some concentration of solid particles, such as wastewater streams.

Benefits of Ultrasonic Flowmeters:

Non-Invasive: Ultrasonic flow meters require no insertion into the fluid, which minimizes the chance of clogging, pressure loss or fouling.

Broad Applicability: Suitable for various liquids, from water to chemicals, and for various industries such as water treatment, oil and gas, chemical and HVAC systems.

High Accuracy: Offer accurate measurements even at low flow rates, making them ideal for both industrial processes and research purposes.

Low Maintenance Requirement: Due to the lack of moving parts and non-invasive nature, ultrasonic flow meters generally require little maintenance.

Conclusion:

Ultrasonic flow meters have proven to be reliable instruments for measuring fluid flows. With their non-invasive operation, wide applicability and high accuracy, they are an essential part of modern flow measurement technology. Their evolution continues, making ongoing contributions to the efficiency and reliability of various industrial processes.